100 Years of Tobacco Research at UKREC

100 Years of Tobacco Research at UKREC

Published on May 21, 2025

Few crops are as significant to Kentucky’s agricultural history and heritage as tobacco. It served as a dominant cash crop for farmers across the state for more than 200 years, with some family farms passing their knowledge down through four or five generations.

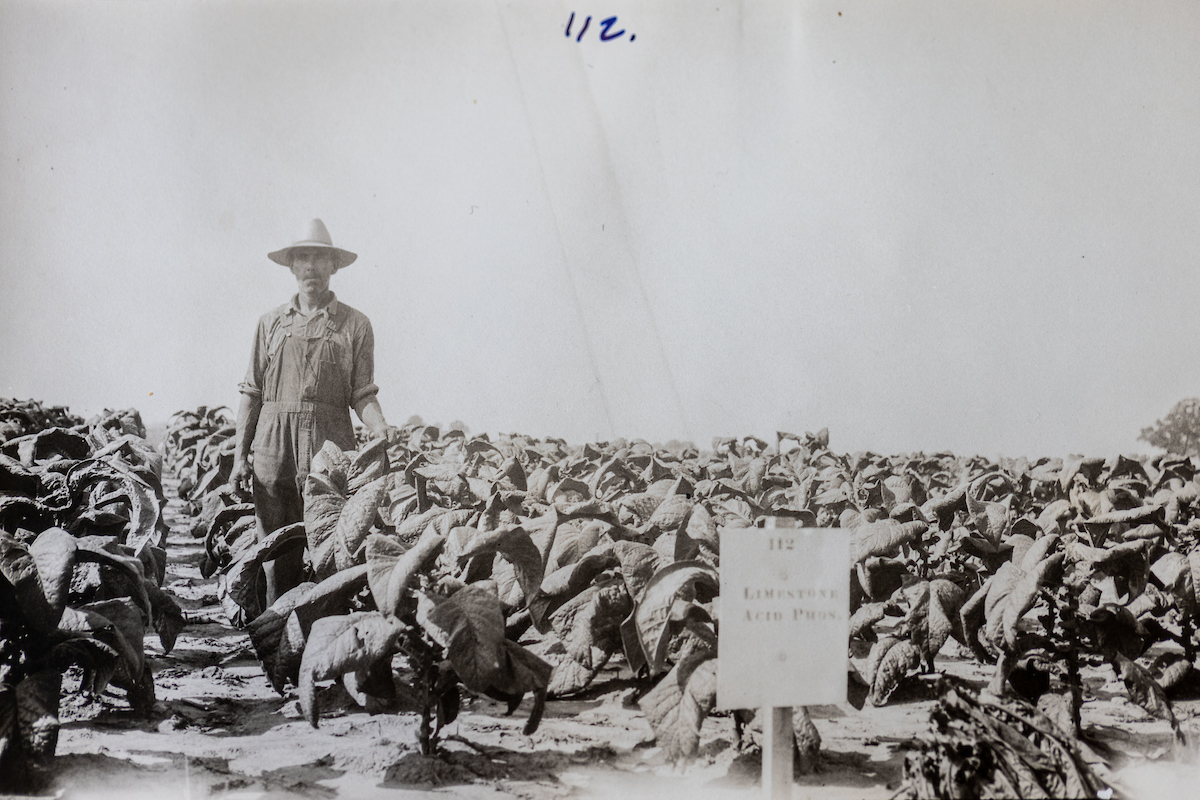

The first tobacco variety trials and research on the effects of fertilizers at the Princeton facility started in 1926, shortly after the farm was founded. The studies in Princeton also represented some of the first tobacco research ever conducted in the state.

Tobacco specialists have been stationed in Princeton continuously since the early 1950s to serve the needs of Kentucky’s growers, a legacy that Andy Bailey, a UK Extension tobacco specialist, inherited when he started in 2002.

UK Extension tobacco specialist Bob Pearce conducted research into the use of no-till farming methods for tobacco during the 1990s and 2000s. In the late 2000s, an alternative conservation tillage system emerged, in which narrow strips were cultivated for planting while the rest of the field was left undisturbed.

Todd Harton, a tobacco grower in Trigg County, was one of the first to implement strip-tillage for tobacco production. Roughly two-thirds of growers in Western Kentucky would adopt strip tillage in their operations, with an additional 10 to 15 percent engaging in no-till tobacco farming.

The Master Settlement Agreement, declining tobacco use, increased international competition, and the end of the federal quota system in 2004 led to a dramatic reduction in Kentucky’s tobacco production in the 21st century. However, the crop remains a significant source of income for growers, particularly in Western Kentucky, where dark tobacco, a heavier type than burley, is cultivated for use in smokeless products such as snuff and chewing tobacco. Tobacco production in Kentucky totaled $225 million in 2022, according to the 2022 USDA Census of Agriculture.

In the early 2000s, some of UKREC’s most influential tobacco research was focused on helping farmers to reduce the presence of harmful compounds in tobacco, specifically nitrosamines, to meet changing industry expectations. The study revealed that the heavy use of increasingly expensive nitrogen contributed to higher nitrosamine levels without improving yields or quality.

“We did a lot of work to focus on what optimal nitrogen rates would be for dark tobacco,” Bailey said. “We really got rid of excess nitrogen application.”

The reduction in nitrogen use by Western Kentucky tobacco growers was a major step toward harm reduction in moist snuff, a domestically produced product made almost entirely from dark tobacco grown in Western Kentucky and parts of northern Tennessee.

Between 2005 and 2015, more tobacco research at UKREC focused on exploring harm mitigation opportunities related to the crop’s curing process. Fire-curing dark tobacco involves a four- to five-week smoldering process, using hardwood slabs and sawdust to impart a unique and world-renowned character to the leaf.

The research results showed that adjusting the timing of the first firing, reducing the duration of firing, and maintaining barn temperatures at no higher than 130°F helped reduce the levels of both nitrosamine and an additional carcinogen related to the fire-curing process, benzopyrene.

UKREC has collaborated with the University of Kentucky and Murray State University to host three annual field day events for tobacco growers in the region, including the Corn, Soybean, and Tobacco Field Day in Princeton. Since 2013, Bailey and Pearce have also been instrumental in providing agronomic guidance to all Kentucky tobacco growers annually as part of the state’s required GAP training.

“We talk to every tobacco grower every year because they are required to come to GAP training in order to sell their crop,” Bailey said.

UK extension professionals have also helped tobacco growers gauge the changing economic landscape for the labor-intensive crop by conducting surveys to assess input costs and producing budgets annually for burley, dark fire-cured tobacco, and dark air-cured tobacco. In recent years, they have also worked to help growers streamline their processes for maximum efficiency, thereby reducing labor costs.

The tornado that struck the Research and Education Center in 2021 dealt a significant blow to the facility’s tobacco infrastructure, destroying all of the tobacco curing barns, including two built in the 1940s that were among the farm’s oldest structures. The tobacco industry quickly reached out to offer help and monetary support in the aftermath. The UK also reaffirmed its commitment to tobacco, and the first permanent structure built at the research station was a dark fire-curing barn.

“There are a lot of states that have tobacco but don’t have university support for tobacco,” Bailey said. “I’m happy that UK is still one that does because it’s still a very important economic crop here in Kentucky.”